- Home

- About us

- Services

- Upstream

- Tubular & OCTG Inspection

- Lifting Gear and Lifting Equipment Inspection

- Crane Load Testing & Inspection

- Derrick Inspection & Remedial

- DROPS Survey and remedial Services

- NDT Inspection

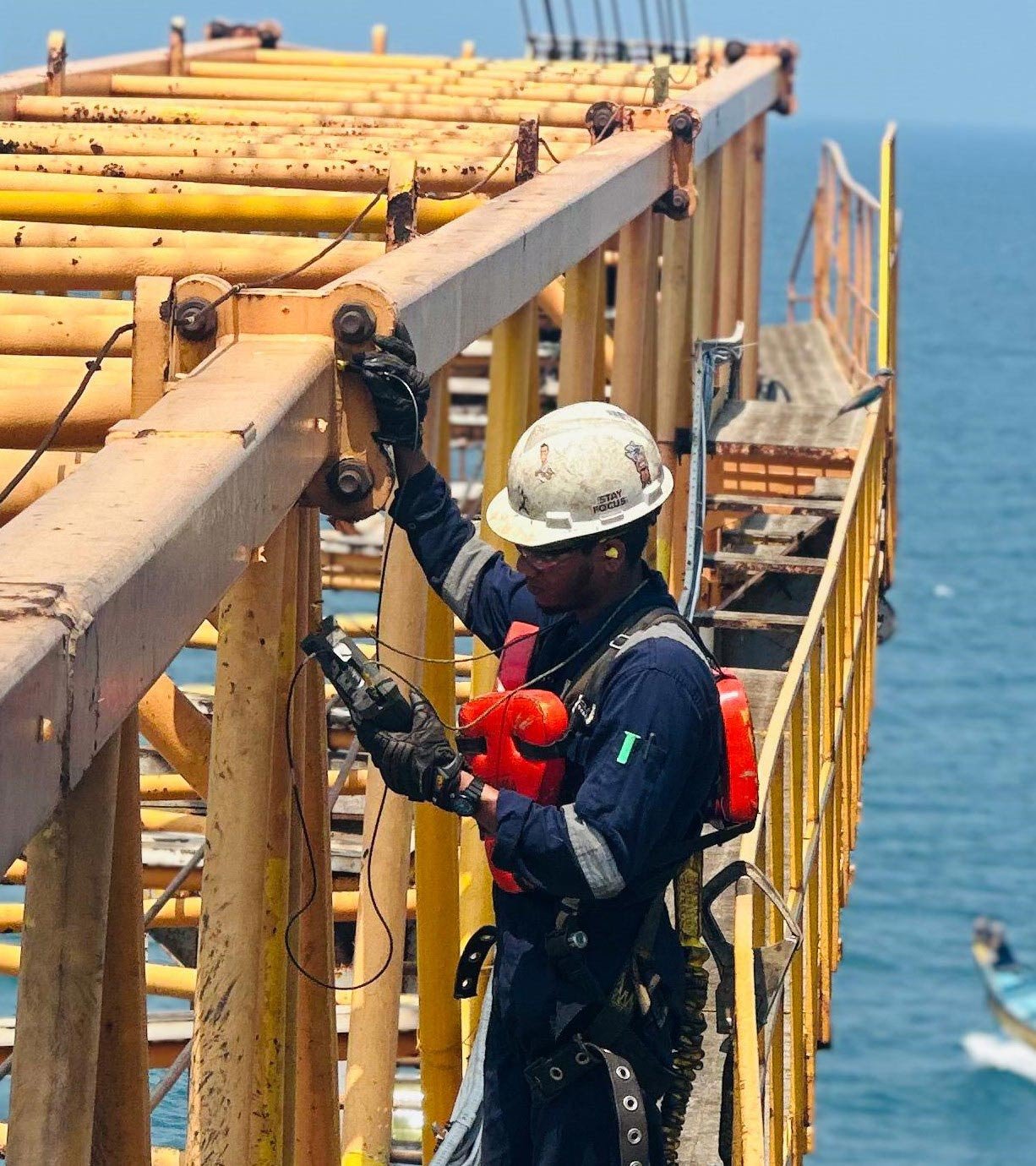

- Rope Access Services

- Special Periodic Surveys with Class Approvals

- Helideck Surveys

- Rig Acceptance Audits

- Tubular Yard Management

- Load Testing Services

- Manpower services

- Inventory Reconciliation

- Downstream

- Marine

- Renewables

- Upstream

- Representations

- Online Reports

- QHSE

- Career

- Contact Us

Ensuring Integrity and Reliability Through Advanced Inspection Techniques

At Tubestar, we offer a comprehensive range of Non-Destructive Testing (NDT) services with or without rope access designed to ensure the safety, integrity, and reliability of your assets. Our advanced inspection techniques help detect defects and irregularities without causing damage to the components being tested, providing you with accurate and reliable data to make informed decisions about maintenance and operations. Our NDT Services includes:

Conventional NDT

Our conventional NDT services utilize time-tested methods to evaluate the properties of materials and components:

- Visual Inspection (VT): A primary method for detecting surface defects and irregularities through direct observation or using tools such as magnifying glasses and mirrors.

- Magnetic Particle Testing (MT): Ideal for detecting surface and slightly subsurface discontinuities in ferromagnetic materials using magnetic fields and ferrous particles.

- Liquid Penetrant Testing (PT): A cost-effective method to reveal surface-breaking defects by applying a liquid dye to the surface and observing the bleed-out pattern.

- Ultrasonic Testing (Thickness Gauging / Flaw Detection): A simple method for detecting the thickness of the metal by using ultrasonic sound waves with the help of suitable probes. The highlight of our UTG machine is that our probes are paint-through.

Eddy Current Testing (ECT)

Eddy Current Testing is an advanced electromagnetic testing method used primarily for detecting surface and near-surface defects in conductive materials. It is highly effective for:

- Crack Detection: Identifying cracks and corrosion in materials without removing protective coatings.

- Inspection without removing paint: Measuring the thickness of coatings and materials with high precision.

- Conductivity Testing: Assessing material properties and detecting material degradation.

Ultrasonic Testing (UT) Flaw Detection

Ultrasonic Testing uses high-frequency sound waves to detect internal flaws in materials. Our UT services include:

- Flaw Detection: Identifying internal cracks, voids, and inclusions in metals, composites, and other materials.

- Thickness Gauging: Measuring the thickness of materials to monitor corrosion and wear.

- Weld Inspection: Evaluating the integrity of welds to ensure they meet required standards.

Borescope Inspection

Borescope inspection allows for the visual examination of areas that are otherwise inaccessible. This method is particularly useful for:

- Internal Inspections: Inspecting the internal components of machinery, pipes, and engines without disassembly.

- Video Documentation: Providing video and photographic evidence of inspection findings for detailed analysis.

Holiday Testing

Holiday testing, also known as spark testing or pinhole detection, is used to identify defects in nonconductive protective coatings on conductive substrates. It is essential for:

- Coating Integrity: Ensuring that coatings on pipelines, tanks, and structures are free from pinholes, cracks, and other defects.

- Corrosion Prevention: Preventing corrosion by verifying the effectiveness of protective coatings.

Pressure Testing

Pressure testing is used to ensure the integrity and safety of pressure vessels, pipelines, and other components that operate under pressure. Our pressure testing services include:

- Hydrostatic Testing: Using water or another liquid to pressurize the component and check for leaks and structural integrity.

- Pneumatic Testing: Using air or another gas to perform leak testing when liquid testing is not feasible.

Leak Testing

Leak testing is crucial for detecting and locating leaks in various systems and components. Our leak testing services include:

- Pressure Decay Testing: Monitoring the hydrostatic pressure within a sealed component over time to identify leaks.

Ensure the integrity and reliability of your assets with Tubestar's expert Non-Destructive Testing (NDT) services. Contact us today to learn more about our services and how we can help you maintain the highest standards of safety and performance of all your critical equipment.

Stay Connected

Reach out to us anytime for assistance